Home Uncategorized Choosing a Carbide Bur – Tech Tip

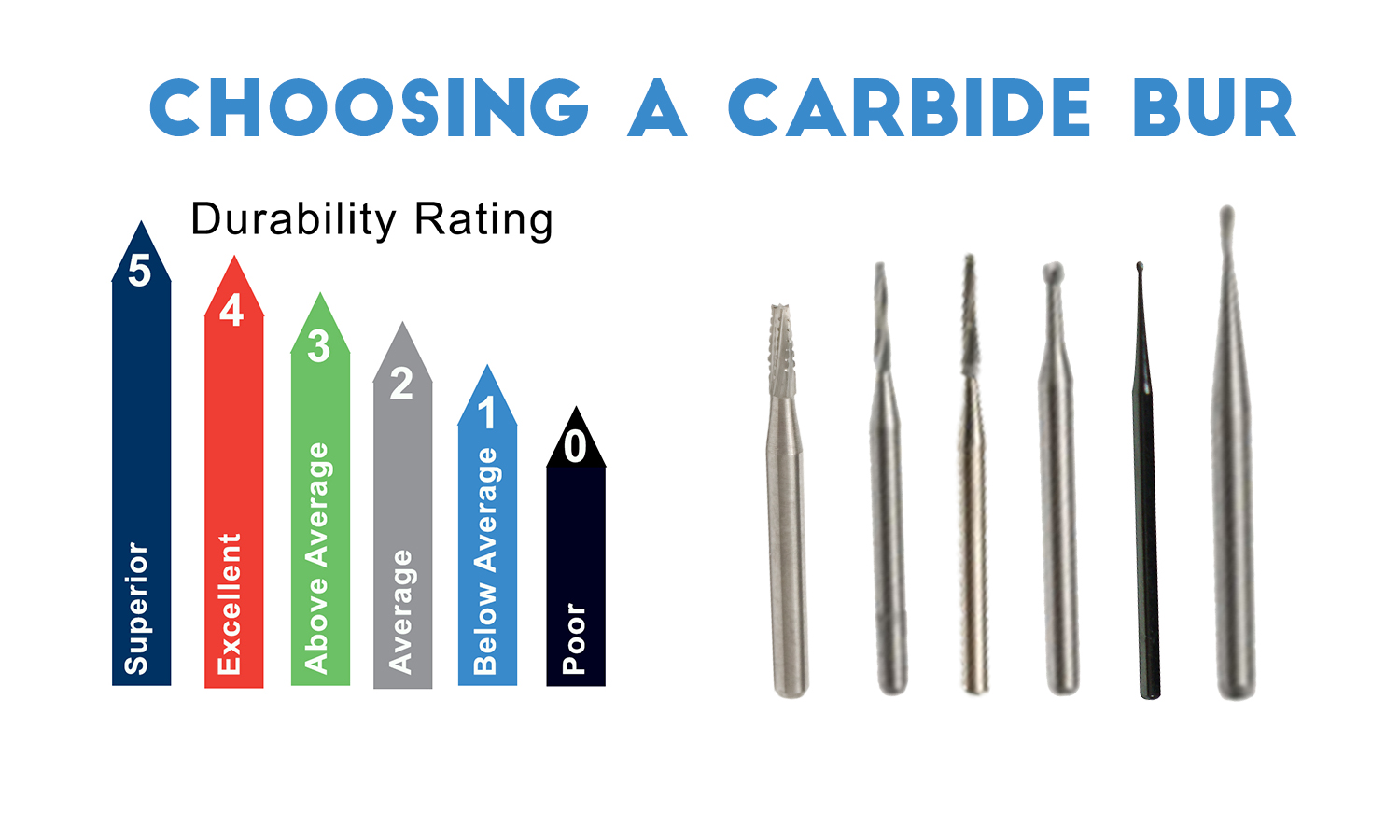

There are three primary reasons for drilling & choosing a carbide bur has its part.

Subscriber exclusive include:

Delta Kits respects your privacy and will never sell your email address and phone number to third party providers.

"*" indicates required fields

1090 Bailey Hill Rd, Ste A

Eugene, OR 97402

sales@deltakits.com